Shipping Industrial Glue and Adhesives from China: Complete DG Compliance Guide 2026

Adhesive rejected at Ningbo port. Cyanoacrylate super glue (UN 1133) was booked as general cargo instead of Class 3 Flammable. The importer now faces $2,500 in storage fees, repackaging, and rebooking.

This happens to 60% of first-time adhesive importers. Three compliance gaps cause rejections: wrong DG classification, missing 2026 QR code documentation, and non-UN-certified packaging.

Critical update: China's Dangerous Chemicals Safety Law requires QR code labels on all DG packaging from May 1, 2026. Non-compliant shipments face rejection.

This guide covers DG classification, UN packaging, shipping costs, customs clearance, and freight forwarder selection for industrial adhesive imports from China.

Why Glue Is Classified as Dangerous Goods

Not all adhesives from China are dangerous goods. Water-based PVA glue used in furniture manufacturing ships as regular cargo. EVA hot melt pellets for packaging lines are non-hazardous. The classification depends entirely on chemical composition and flash point.

Solvent-Based vs. Water-Based Chemistry

Solvent-based adhesives contain flammable chemicals (toluene, acetone, ethyl acetate) with flash points from -17°C to 23°C, placing them in UN Class 3. Water-based adhesives use polymer dispersion in aqueous solution with no flammable vapor, shipping as standard freight. Hybrid formulations with even 15% solvent content trigger DG classification regardless of marketing claims about water content.

UN Class 3: Flammable Liquids

Most industrial adhesives from China fall into UN Class 3 (Flammable Liquids). This includes:

Cyanoacrylate super glue (UN 1133): Flash point -20°C, Packing Group II

Contact cement spray (UN 1950): Aerosol propellant plus flammable adhesive base

Epoxy resin Part A (UN 1866): Flash point 30°C, requires temperature monitoring

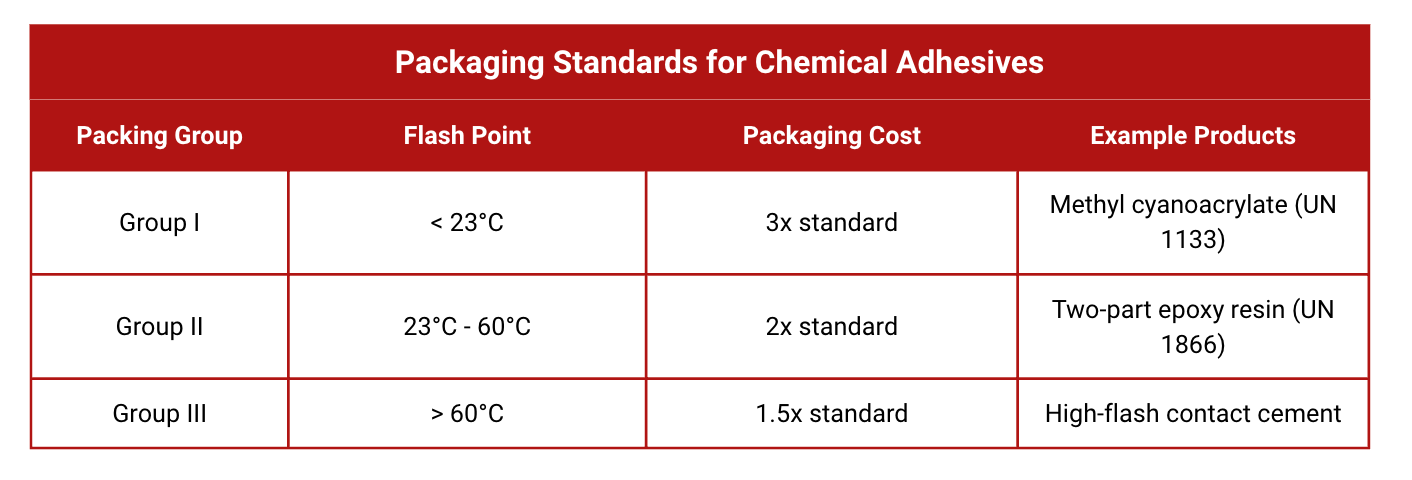

Your cargo's Packing Group (I, II, or III) determines packaging requirements and shipping costs. Group I is highest danger and most expensive. Most Chinese adhesive exports are Group II or III.

UN Class 6.1: Toxic Substances

Specialty adhesives with toxic components above regulatory thresholds (polyurethane with free isocyanates UN 2206, resorcinol-formaldehyde glue UN 2810) require additional hazard labels and cannot mix with food-grade cargo in LCL shipments.

UN Class 9: Miscellaneous Hazardous Materials

Silicone sealants exceeding VOC limits (UN 3082) and reactive hot melt adhesives classify as Class 9 environmentally hazardous substances. Ocean carriers require DG booking despite suppliers claiming products are "safe."

When Adhesives Are Non-DG

Water-based PVA wood glue, standard EVA hot melt pellets, pressure-sensitive adhesive (PSA) without solvent content, and pre-cured silicone strips ship as regular cargo with no DG requirements. Always verify with your supplier's Cargo Transport Condition Report from authorized Chinese institutes.

Essential Documentation and Compliance Requirements

Documentation failures cause 70% of adhesive shipment delays. Missing one document triggers rejection, storage fees, and restart from zero.

Critical Documents Required

MSDS/SDS (Safety Data Sheet): Must follow GHS 16-section format with English and Chinese versions, revision date within 3 years, and Section 14 transport information showing UN number, proper shipping name, and packing group. Request directly from the manufacturing chemist, not sales teams who often provide outdated templates.

Cargo Transport Condition Report: This is the most important document. Issued by authorized Chinese institutes (Shanghai Chemical Industry Research Institute, Guangzhou Entry-Exit Inspection Bureau, China Classification Society), it costs $150-300 and takes 3-5 days. It definitively states whether cargo is DG, applicable UN number, proper shipping name, class and packing group. Airlines and ocean carriers will not accept bookings without this document.

2026 China Chemical QR Code System: Under China's updated Dangerous Chemicals Safety Law, all DG shipments require electronic QR code labels on packaging linked to the National Chemical Database.

The regulation officially takes effect May 1, 2026, though many exporters began compliance preparation in early 2026. Each code contains manufacturer registration, product formula ID, batch date, UN classification, and shipment tracking.

Only registered Chinese manufacturers can generate these codes through the government portal. Shipments without compliant QR codes will face rejection at Chinese ports from May 2026 onward.

Additional Export Documents: Commercial invoice listing UN numbers, packing list with box-level detail, Certificate of Origin, DG Declaration Form signed by shipper, and fumigation certificate for wooden pallets in LCL shipments.

Packaging Standards for Chemical Adhesives

Packaging failures cause more rejected shipments than any other issue. Properly classified adhesives with perfect documentation get refused if outer cartons lack UN certification markings.

UN-Rated Packaging Requirements

UN-rated packaging means containers passed standardized drop, stacking, and pressure tests. Look for codes stamped on approved containers: 4G/Y14.5/S/24

Code breakdown:

4G: Fiberboard box

Y: Packing Group II

14.5: Maximum gross weight in kilograms

S: Solids (or L for liquids)

24: Year of manufacture (2024)

Never use standard commercial cartons for DG adhesives. Carriers reject them immediately even if they look identical to UN-rated boxes.

Inner Packaging and Leak Prevention

Liquid adhesives require three-layer packaging:

Primary containment: Metal cans or chemical-resistant plastic bottles with 10-15% headspace for thermal expansion. Use tamper-evident closures, not regular screw caps.

Secondary containment: HDPE bags (minimum 150 microns) with absorbent material (vermiculite or clay granules) sufficient to absorb 150% of inner container volume.

Tertiary packaging: UN-rated outer box with internal dividers preventing container contact, cushioning foam, and pressure-sensitive tape rated for export shipping.

In our experience with liquid epoxy from Guangdong, 95% of packaging failures occur when suppliers use regular plastic bottles without proper closure reinforcement. Invest in tamper-evident closures ($0.15-0.30 per bottle) to prevent damage claims.

Labeling Requirements

Every DG package needs:

UN Number and Proper Shipping Name: Printed on two opposite sides in 12mm+ letters

Hazard Diamond Labels: Class 3 (red/flame), Class 6.1 (white/skull), Class 9 (black-white striped)

Orientation Arrows: On two opposite sides and top for liquid containers

Shipper/Consignee: Full names, addresses, contact numbers in English

Limited Quantity (LQ) Marking: If qualifying for LQ exception

Labels must withstand 3-month seawater exposure. Use polyester or vinyl with UV-resistant ink, not paper labels.

Most Chinese adhesives are Group II or III. Source UN-rated packaging from specialized suppliers like Qingdao Laf Packaging or Shanghai Xinnuo Packaging. Standard packaging factories lack certification documentation.

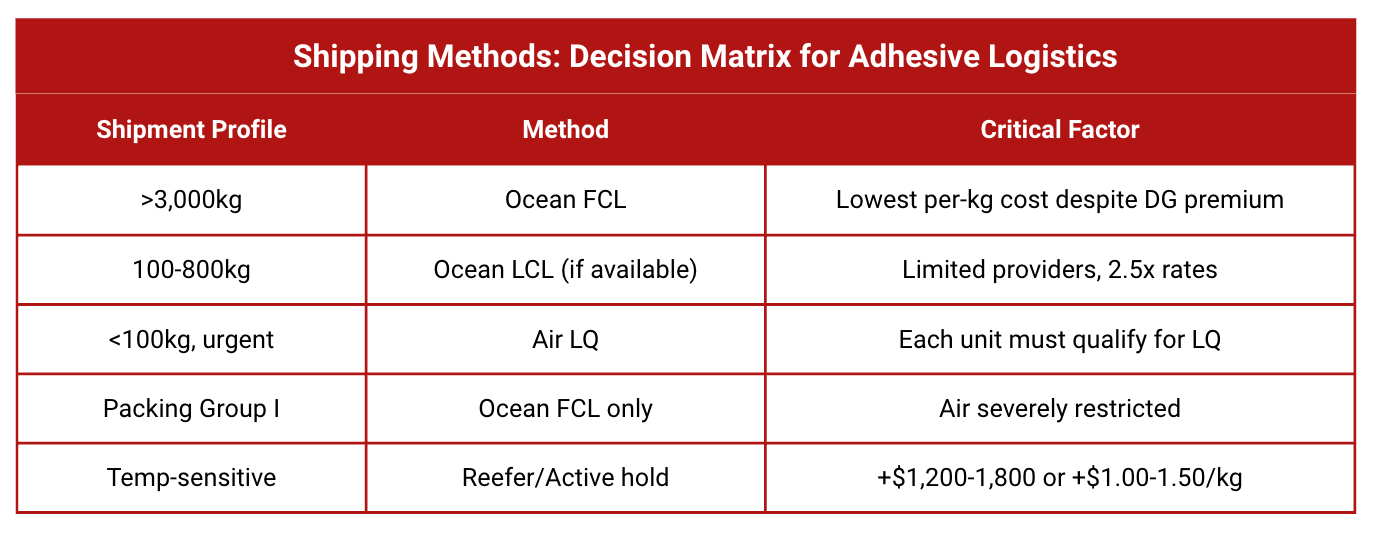

Shipping Methods: Decision Matrix for Adhesive Logistics

Ocean Freight DG Requirements

FCL booking requirements:

DG Declaration Form: 7-10 days before departure

UN-certified packaging mandatory

MSA container inspection for certain UN classes

DG cost premiums:

20ft container: +$800-1,200

40ft container: +$1,200-1,800

Documentation + port handling: +$250-500

LCL reality: Most consolidators refuse DG cargo. Available providers charge 2.5-3x standard rates ($180/CBM vs. $65/CBM for non-DG). Expect 5-7 day delays beyond standard transit.

Air Freight: Limited Quantity (LQ) Strategy

LQ qualification unlocks 50-70% cost savings:

Inner container ≤1L (liquids) or ≤1kg (solids)

Outer package ≤30kg gross weight

Packing Group II or III only

Requires LQ diamond marking

Cost comparison:

LQ rates: $5.50-8.00/kg

Full DG rates: $9.00-13.00/kg

Maximum volume: 600-800kg per consignment

Class 3 consolidation restrictions: Cannot mix with Class 1 (Explosives), Class 5 (Oxidizers), or food-grade cargo in LCL. Packing Group I requires dedicated FCL container.

Customs Clearance and Import Tariff Requirements

Customs classification determines your total landed cost. A single-digit error in the HS code can trigger incorrect tariff rates, causing delays, surprise duties, or even shipment rejection. Adhesive classification under the Harmonized Tariff Schedule involves multiple decision points.

HS Code 3506: Prepared Glues and Adhesives

HS Code 3506 covers the majority of industrial adhesives:

3506.10: Products suitable for use as glues or adhesives, put up for retail sale as glues or adhesives, not exceeding a net weight of 1 kg

3506.91: Adhesives based on polymers of headings 3901 to 3913 or on rubber

3506.99: Other (including adhesives based on natural products)

Most B2B adhesive shipments from China fall under 3506.91 (polymer-based) or 3506.99 (other formulations). This distinction matters for tariff calculation.

US tariff rates for HS 3506:

Base rate: 6.5% (Most Favored Nation)

Section 301 tariff: Additional 25% (applies to Chinese origin)

Total effective rate: 31.5%

EU tariff rates for HS 3506:

Base rate: 6.5%

No additional China-specific tariffs

Total effective rate: 6.5%

Always verify the current Section 301 status. Recent trade negotiations have created exemption processes for certain adhesive subcategories. Your customs broker should confirm whether your specific product qualifies for exemptions.

HS Code 3214: Glaziers' Putty, Sealants

HS Code 3214 applies to:

3214.10: Glaziers' putty, grafting putty, resin cements

3214.90: Other (including caulking compounds and sealants)

Silicone sealants, polyurethane construction foam, and MS polymer hybrid sealants typically classify under 3214.90.

US tariff rates for HS 3214:

Base rate: 3.7%

Section 301 tariff: Additional 25%

Total effective rate: 28.7%

EU tariff rates for HS 3214:

Base rate: 6.5%

Total effective rate: 6.5%

The tariff difference between 3506 and 3214 is minimal after Section 301 tariffs apply. However, the distinction matters for non-tariff regulations. 3214 products may face VOC content restrictions under environmental regulations, while 3506 products may require different safety certifications.

The Critical Classification Decision

How do you distinguish between 3506 and 3214? The key question is application method:

3506 (Adhesives): Applied to join two or more surfaces together. The adhesive becomes part of the permanent bond structure. Examples: structural epoxy, wood glue, industrial cyanoacrylate.

3214 (Sealants): Applied to fill gaps, joints, or seams to prevent passage of liquids or gases. The sealant remains elastic or deformable. Examples: silicone window sealant, polyurethane joint filler, construction caulking.

Hybrid products create classification disputes. A "construction adhesive" that both bonds and seals falls into a gray area. We recommend classifying based on the primary intended use stated in the product technical data sheet. If the manufacturer describes it as "bonding plywood panels," use 3506. If they describe it as "weatherproofing window frames," use 3214.

Import Documentation for Customs

Present these documents to customs at destination:

Required documents:

Commercial invoice with correct HS code

Packing list showing individual carton details

Bill of Lading or Airway Bill

MSDS (English version)

Certificate of Origin (if claiming preferential tariff treatment)

Additional documents for DG shipments:

Cargo Transport Condition Report from Chinese institute

DG Declaration Form

Import permit (if required by destination country for certain chemicals)

Country-specific requirements:

United States: Advance filing through Automated Commercial Environment (ACE) required. Entry summary (CBP Form 7501) must be filed within 10 days of arrival. Additional EPA or OSHA notifications may apply depending on chemical composition.

European Union: REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) compliance is mandatory. EU importer must confirm adhesive formulation is registered in REACH database. Non-registered chemicals face import bans.

Middle East: Key markets include:

UAE/Saudi Arabia/Qatar: GCC Standardization Organization (GSO) technical regulations apply

Pre-shipment certificates of conformity often required

Halal certification needed for certain consumer adhesive products

Choosing the Right Freight Forwarder for Chemical Logistics

Most freight forwarders claim DG capability but few possess proper expertise and licensing. Wrong choice causes delayed shipments, surprise charges, and compliance failures.

Essential Certifications to Verify

China Dangerous Goods Transport License: Forwarder must hold certification from China Maritime Safety Administration (ocean) or Civil Aviation Administration (air). Request license number and verify through government portal.

IATA DG Training: For air freight, staff need current IATA Dangerous Goods Regulations certificates (renewed annually). Ask to see training certificates for personnel handling your shipment.

DG Insurance: Standard cargo insurance excludes dangerous goods. Forwarder needs specialized DG liability coverage with minimum $2 million per occurrence.

Operational Competence Indicators

Port coverage: Direct operations at Guangdong (Shenzhen, Guangzhou), Zhejiang (Ningbo), and Shanghai ports, not subcontracted to local agents.

Carrier relationships: Contract rates with ocean carriers for DG cargo. Spot-market rates cost 40-60% more than contract rates.

Documentation accuracy: Request sample DG Declaration Forms. Check completeness of UN number, proper shipping name, class, packing group, emergency contact information.

Red Flags to Avoid

Asking you to provide all documentation (competent forwarders prepare DG Declarations themselves)

Quotes significantly below market rates (indicates hidden fees or non-compliance)

Claims "we can ship anything as general cargo" (willingness to misclassify)

Can't explain difference between Packing Group II and III (fundamental knowledge gap)

Gerudo Logistics: Your DG Chemical Specialist

Gerudo Logistics specializes in dangerous goods and chemical exports from China with 15+ years of experience handling Class 3, 6.1, and 9 adhesive shipments.

Our DG Capabilities:

Port Network: Direct operations at Guangzhou, Shenzhen, Shanghai, Ningbo, Qingdao, and Dalian with dedicated DG booking channels.

2026 QR Code Compliance: We assist suppliers with China's chemical traceability system registration and verify label compliance before export.

Factory Inspection: Pre-shipment packaging and labeling verification at supplier facilities. Catches 90% of compliance issues before trucking to port.

Documentation Management: Complete DG Declaration preparation, MSDS coordination, and Cargo Transport Condition Reports.

Customs Coordination: Partner brokers in US, EU, and Middle East pre-clear HS code classifications to prevent destination surprises.

Upload your product MSDS for free classification assessment. We'll confirm DG protocols and provide transparent landed cost quotations within 24 hours.

Frequently Asked Questions

Is all glue from China considered Dangerous Goods?

No. Water-based PVA glues and most hot melt adhesives are non-hazardous. Solvent-based glues, flammable aerosols, and certain epoxies classify as UN Class 3, 6.1, or 9 requiring specialized handling. Request a Cargo Transport Condition Report from your supplier to verify classification.

What is the Electronic QR Code requirement for 2026?

Effective May 1, 2026, all DG shipments need QR code labels on packaging linked to China's national chemical database under the Dangerous Chemicals Safety Law. Your supplier generates this through the government portal. Freight forwarders cannot create these codes. Shipments without QR codes will face rejection at Chinese ports from May 2026 onward.

Can I ship small quantities of glue via air freight?

Yes, under Limited Quantities (LQ) exception if each inner package is ≤1L (liquids) or ≤1kg (solids), gross weight ≤30kg per box, product is Packing Group II or III, and package displays LQ marking. This reduces air freight costs by 50-70% compared to full DG rates.

What is the difference between HS Code 3506 and 3214?

HS 3506 covers adhesives designed to bond surfaces permanently. HS 3214 covers sealants designed to fill gaps and prevent liquid/gas passage. Classification affects tariff rates and regulations. Using wrong code can trigger 25% Section 301 surcharges in US market.

Does humidity during sea transit affect glue quality?

Yes. Industrial adhesives often require 10-25°C storage with <60% humidity. Ocean containers crossing tropical routes can reach 35-45°C and 80-90% humidity, causing premature curing, separation, or contamination. Consider reefer containers ($1,200-1,800 premium per 20ft) for sensitive adhesives.

What is a UN-Certified box and where do I buy them?

UN-certified boxes passed standardized drop, stack, and pressure tests. Look for codes like "4G/Y14.5/S/24" indicating box type, rating, and manufacture year. Source from Qingdao Laf Packaging or Shanghai Xinnuo Packaging. Never use regular cartons or reuse UN-rated boxes once opened.

How do I get a Certification for Safe Transport of Chemical Goods?

Submit product MSDS and samples to authorized Chinese institutes (Shanghai Chemical Industry Research Institute, Guangzhou Entry-Exit Bureau, China Classification Society). Cost is $150-300, processing takes 3-5 business days. This certificate is mandatory for booking DG freight.

Conclusion

Shipping industrial adhesives from China requires accurate DG classification, complete documentation, and UN-certified packaging. Compliance prevents rejected shipments, storage fees, and penalties. The May 2026 QR code regulation under China's Dangerous Chemicals Safety Law becomes mandatory for all DG exports.

Three critical factors determine success: correct UN class identification (Class 3, 6.1, or 9), proper packaging meeting packing group requirements, and working with freight forwarders who hold current DG certifications. A $400 DG surcharge prevents $4,000 in port delays and compliance penalties.