Understanding Cargo Classification in 2026: General, Sensitive, Dangerous Goods, and Prohibited Items from China

A $50,000 shipment sits in a warehouse, going nowhere. The problem started when the importer classified their cargo incorrectly.

Cargo classification determines which carriers accept your shipment, what documentation you need, and which customs pathway your goods follow. Most import failures happen because of wrong classification before cargo leaves the factory.

This guide helps you complete accurate self-assessment.

We will walk through the four main cargo categories you need to understand: general cargo, sensitive cargo, dangerous goods, and prohibited cargo. More importantly, you will learn exactly where the boundaries are and when you need to escalate to specialist handling.

General Cargo: Where Logistics Is Predictable

Definition: What Qualifies as General Cargo

General cargo is straightforward. It has no hazardous properties, requires no temperature control, and carries no compositional or regulatory sensitivities. This is the cargo that moves through the global supply chain with minimal friction.

When you ship general cargo, you are working with predictable timelines, standard documentation, and competitive pricing. Customs clearance follows routine procedures. Carriers accept bookings readily. Insurance rates stay reasonable.

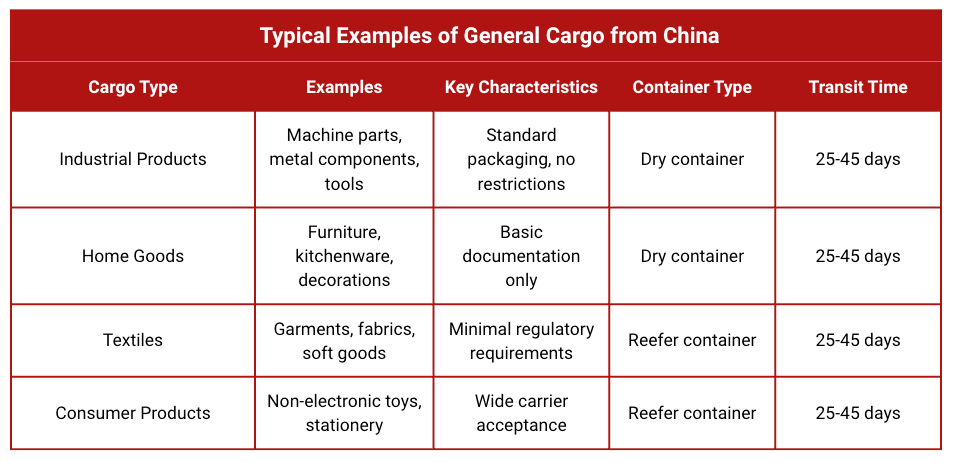

Typical Examples of General Cargo from China

Most Chinese factory exports fall into this category:

Ordinary industrial products like metal parts and machinery components

Furniture, textiles, garments, plastic housewares

Standard consumer goods without batteries or electronics

Products requiring only basic commercial documentation

Why General Cargo Is Predictable

The appeal of general cargo lies in control. Cost, lead time, and risk are highly controllable variables. You can compare quotes from multiple forwarders, predict transit times accurately, and manage risk through standard insurance.

Carrier availability is wide. Most shipping lines and airlines accept general cargo without special requirements or advance approval. Booking space is usually straightforward, even during peak seasons.

The Boundary: When Cargo Stops Being “General”

The moment your shipment involves food products, temperature control, chemical properties, or energy-related attributes, it no longer qualifies as general cargo.

Once you cross this boundary, logistics complexity increases significantly. Standard freight forwarders may accept your booking but often lack the infrastructure and expertise your cargo needs.

Sensitive Cargo: Where Most Import Problems Begin

This is the category that causes the most confusion and the most expensive mistakes. Sensitive cargo sits in an uncomfortable middle ground. It is not dangerous goods, but it is not simple either.

Definition: What Makes Cargo "Sensitive"

Sensitive cargo is not classified as dangerous under international regulations. However, it faces restrictions at carrier, customs, or destination country regulatory levels. The risk comes from being underestimated. Importers treat it like general cargo and then face rejection, delays, or failed customs clearance.

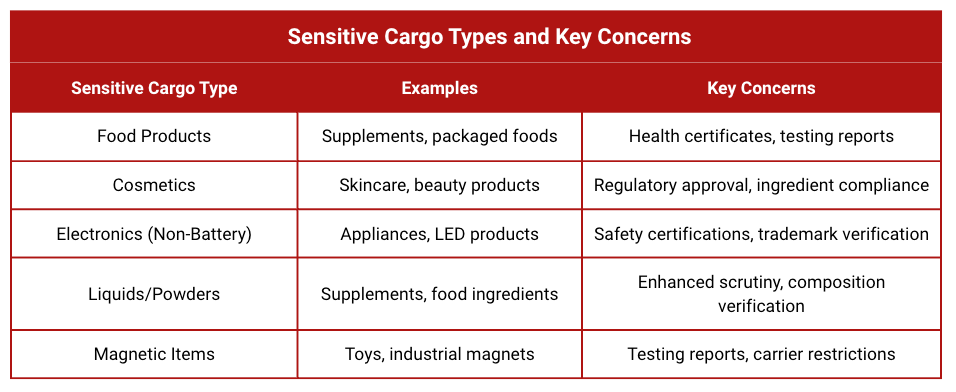

Common Sensitive Cargo Importing from China

Food and Food Ingredients

Any product intended for human consumption falls into sensitive cargo. This includes packaged food products, food additives, ingredients, and dietary supplements. You need health certificates, certificates of origin, laboratory test reports, and often pre-approval before shipment. Ingredient lists must comply exactly with destination labeling laws.

Cosmetics and Health Products

Skincare products, beauty items, and nutritional supplements face regulatory scrutiny. The European Union requires notification under the Cosmetics Regulation. The United States FDA has specific labeling and ingredient disclosure requirements. Ingredient lists must meet destination country standards, which often differ from Chinese regulations.

Electrical Products Without Lithium Batteries

Consumer electronics without lithium batteries still qualify as sensitive cargo. Electrical safety certifications vary by country. CE marking for Europe, UL certification for the United States. Customs authorities examine these products for trademark compliance and safety standards.

Products Containing Liquids, Powders, or Magnetic Materials

These categories trigger additional carrier scrutiny. Liquid supplements need composition declarations. Protein powders require detailed testing reports. Products with magnetic materials need magnetism testing. Carriers often impose quantity limitations and require advance notification.

Why Sensitive Cargo Is Frequently Mismanaged

Documentation, Labeling, and Compositional Issues Ingredient lists must match destination requirements exactly. Labels need specific information in the correct language. Certificates must come from recognized laboratories. Missing documentation gets discovered during customs examination, not before shipment.

High Inspection Rates and Uncontrollable Processing Times Sensitive cargo faces higher customs examination rates than general cargo: Food products and cosmetics commonly see 30% to 50% examination rates compared to 5% to 10% for general cargo. Physical inspections add 3 to 7 days minimum.Laboratory testing can extend delays to 2 to 4 weeks.

Standard Forwarders Lack Front-End Risk Assessment Most general freight forwarders accept sensitive cargo bookings because they look simple on paper. Problems emerge when cargo arrives at destination. Experienced sensitive cargo specialists conduct front-end risk assessment, reviewing product specifications and identifying documentation gaps before shipment.

Frozen Food and Temperature-Sensitive Cargo

Cold Chain Cargo as the Highest-Risk Sensitive Category

Frozen food is not classified as dangerous goods. However, it is highly time-sensitive and temperature-sensitive cargo. Within sensitive cargo, frozen food carries the highest failure cost. The risk comes from time and temperature, not from hazard properties.

Typical Frozen Food in B2B Imports from China

Frozen meat and poultry products for restaurants and food service

Frozen seafood: fish, shrimp, shellfish

Frozen vegetables and fruits for manufacturing

Frozen prepared meals: dumplings, dim sum, spring rolls

Ice cream and frozen desserts

Standard frozen products require -18°C to -25°C. Ultra-frozen seafood needs -30°C or lower.

Why Frozen Food Fails Commercially

Time becomes money directly. Every delay reduces your sellable period. Health inspection requirements at destination ports are strict. Physical examination often requires thawing samples or laboratory testing. Each delay day reduces remaining shelf life.

Consider this scenario: Your frozen seafood has 12 months shelf life. Ocean transit takes 30 days. Normal clearance takes 3 days. You deliver with 11 months remaining. But add customs examination (7 days), laboratory testing (5 days), and documentation issues (3 days), you lose 15 days. Your remaining shelf life drops below buyer minimum requirements even though product quality is acceptable.

Risk concentrates at ports and customs clearance, not during ocean transit. Vulnerabilities appear when cargo sits at port:

Port cold storage facilities have limited capacity and high costs

Reefer containers need continuous power supply during port dwell time

Coordination between shipping line, port authority, customs, and final cold storage must be seamless

Port congestion can interrupt cold chain for days

Customs examination facilities may lack proper refrigeration

Why Frozen Food Requires Specialist Cold-Chain Handling

Cold chain failure is irreversible. Once temperature breach occurs, product quality cannot be restored. Bacterial growth begins immediately. Insurance claims require temperature data logger evidence, but claims do not recover your market opportunity.

End-to-end cold chain requires specialized infrastructure:

24/7 monitoring with immediate response to temperature deviations

Pre-arranged backup power systems at ports

Established relationships with port cold storage facilities

Experience navigating customs procedures for perishables

Contingency planning accounting for time-sensitive nature

Standard forwarders check temperature when containers arrive. By then, any breach has already occurred. If your sensitive cargo is frozen food, specialist cold-chain handling becomes critical.

Dangerous Goods: When Compliance Becomes the Baseline

With dangerous goods, compliance is the absolute baseline. You either comply fully or your cargo does not move.

Definition: DG Under IATA / IMDG / ADR

Dangerous goods are strictly regulated under international frameworks:

IATA (International Air Transport Association) governs air shipments

IMDG (International Maritime Dangerous Goods) Code covers sea transport

ADR applies to road transport in many destination countries

These regulations exist because dangerous goods pose safety risks during transport. Compliance is mandatory under international treaties.

Read and understand the 9 UN classification of DG goods

Common Dangerous Goods Shipped from China

Lithium Batteries: The Most Commonly Misclassified Dangerous Goods

All lithium batteries fall under Class 9 dangerous goods regulations. Classification depends on battery type (lithium-ion versus lithium metal), watt-hour rating, packaging method, and transport mode.

Different UN numbers apply: UN3480 for lithium-ion batteries shipped alone, UN3481 for batteries packed with or in equipment.

All lithium batteries require:

UN38.3 testing certification proving safety under transport conditions

Proper dangerous goods documentation

Advance booking (7-14 days minimum)

State of Charge restrictions for air transport (30% maximum)

Attempting to ship lithium batteries without proper DG compliance is the single most common cause of shipment rejection for electronics importers. The rejection rate for improperly declared battery shipments exceeds 60% in some major ports. For detailed guidance, refer to our comprehensive battery shipping guides.

Chemicals, Adhesives, Inks, and Aerosols: Typical DG from China

Industrial paints and coatings typically fall under Class 3 (flammable liquids) when flash point is below 60°C. Flash point testing determines exact classification and packing group. Lower flash points create higher hazard levels requiring stricter packaging.

Adhesives and sealants with flammable solvents face similar requirements. Water-based adhesives may not be DG, but solvent-based products almost certainly are.

Printing inks and dyes often contain flammable or corrosive components. Classification requires analysis of the SDS to identify which components trigger DG classification. Many manufacturers provide incomplete or inaccurate SDS documents, creating classification challenges.

Aerosol products including hairspray, spray paint, air fresheners, and cleaning sprays classify as Class 2 (gases) because of pressurized propellant. This applies even when the product itself is not particularly hazardous.

Perfumes and fragrances with high alcohol content qualify as Class 3 flammable liquids. The alcohol percentage determines classification. Products above certain thresholds require full DG compliance.

Each requires Safety Data Sheet, dangerous goods declaration, UN-certified packaging, and proper labeling.

Consequences of Misdeclared Dangerous Goods

Immediate Consequences:

Cargo rejected and returned to origin

Shipment detained at port (7-21 days investigation)

Emergency repackaging costs: $5,000-$15,000 per container

Weeks or months of delay

Financial and Legal Penalties:

Maritime authority fines: $5,000-$25,000 per incident

Aviation authority fines: up to $50,000

Carrier penalties: $1,000-$10,000

Storage and demurrage costs during detention

Voided cargo insurance for misdeclared DG

Criminal prosecution possible in serious cases

Long-Term Impact:

Carrier blacklisting affecting all future shipments

Customer confidence loss

Increased customs scrutiny on all shipments

Why Dangerous Goods Require Specialist Handling

Not all freight forwarders are authorized to handle all DG classes. Carriers maintain approved forwarder lists. You need IATA-certified staff for air freight and IMDG-trained personnel for sea freight.

Specialist DG forwarders provide:

Proper classification and documentation preparation

Understanding of carrier-specific restrictions

Knowledge of destination country DG regulations

Emergency repackaging provider relationships

Problem-solving for documentation issues

At Gerudo Logistics, our IATA and IMDG certified team handles dangerous goods shipments daily. We conduct pre-shipment classification review, arrange proper documentation and packaging, and ensure first-time compliance. Our rejection rate for properly prepared DG shipments is under 2%, compared to industry averages exceeding 15%.

Prohibited Cargo: Risks That Cannot Be Managed

Prohibited cargo is explicitly banned under law or international conventions. No compliant transportation pathway exists.

Universally Prohibited Items

Weapons and military equipment (outside government channels)

Narcotics and controlled substances

Counterfeit goods and trademark violations

Certain hazardous waste materials

Country-Specific Restrictions

Each destination maintains its own prohibited items list. Always verify through destination country customs authority websites, HS Code databases, and trade compliance platforms before placing orders.

Consequences

Customs authorities seize prohibited cargo and destroy it with no compensation. Criminal prosecution is possible. Permanent blacklisting from customs authorities affects future import ability. Business license revocation can occur in severe cases.

How to Classify Your Cargo Correctly

Self-Assessment Decision Tree

Step 1: Check for Dangerous Properties

Does your product contain chemicals, batteries, flammable materials, or compressed gases? Review dangerous goods section and consult DG specialist.

Step 2: Assess Temperature Sensitivity

Does your product require frozen, chilled, or controlled temperature storage? You need cold chain logistics.

Step 3: Identify Regulatory Sensitivities

Is your product food, cosmetics, health supplements, or medical devices? Does it contain liquids, powders, or magnetic materials? These move cargo into sensitive category.

Step 4: Default Classification

If none apply, your cargo likely qualifies as general cargo. Verify with your freight forwarder.

Essential Information to Gather from Suppliers

Complete product specifications and ingredient lists

Safety Data Sheets for chemical-containing products

Battery specifications with watt-hour ratings and UN38.3 certificates

HS Code classification (6-digit minimum)

Existing certifications (FDA, CE, health certificates)

Storage temperature requirements if applicable

When to Escalate to Specialist Freight Forwarders

Escalate immediately for:

Any uncertainty about hazardous classification

Products requiring temperature control

Lithium batteries or battery-containing products

First-time shipping of new product categories

High-value time-critical shipments

Gerudo Logistics provides pre-shipment classification review for dangerous goods and temperature-sensitive cargo. Contact us now for a free cargo assessment.

Best Practices Checklist for Importers

Before Placing Your Order

Request detailed product specifications including all ingredients

Obtain Safety Data Sheets for chemical products

Verify HS codes with your freight forwarder

Confirm destination country requirements

Budget extra lead time (2-4 weeks) for non-general cargo

For Frozen Food and Temperature-Controlled Shipments

Validate supplier cold storage capabilities

Calculate transit time vs. product shelf life

Arrange temperature monitoring devices

Confirm power availability at transshipment points

Plan for customs inspection delays

For Dangerous Goods Shipments

Start booking immediately after order confirmation

Ensure UN-certified packaging

Prepare complete documentation with supplier

Allow 2-3 weeks minimum for carrier approval

Verify destination port DG acceptance policies

Choosing the Right Logistics Partner

Look for:

Relevant certifications (IATA/IMDG for DG, cold chain certifications)

Demonstrated experience with your commodity type

Transparent communication about risks

Proactive compliance approach

References from similar shippers

Frequently Asked Questions Shipping From China

What is the difference between sensitive cargo and dangerous goods?

Sensitive cargo requires enhanced documentation but lacks hazardous properties. Dangerous goods have safety risks requiring IATA/IMDG compliance, UN-certified packaging, and specialized handling.

How do I know if my frozen food needs specialist cold-chain handling?

All frozen food requires cold chain logistics. Specialist handling is critical when products have limited shelf life, need strict -18°C compliance, or face potential inspection delays.

Are all lithium batteries classified as dangerous goods?

Yes, all lithium batteries are Class 9 dangerous goods requiring UN38.3 certification and proper DG documentation.

What certifications should my freight forwarder have for dangerous goods?

IATA-certified DG staff for air freight and IMDG-trained personnel for sea freight with current training certificates.

How much advance notice for reefer container booking?

Minimum 2-3 weeks during normal seasons, 4-6 weeks during peak periods.

What happens if cargo is misclassified?

Carriers reject shipments, authorities impose fines ($5,000-$50,000), insurance voids coverage, and blacklisting affects future shipments.

How much more expensive is DG or frozen food shipping?

DG adds $200-$800 per container plus documentation costs. Frozen food costs 150-300% above standard rates plus monitoring and cold storage fees.

Conclusion: Classification Determines Success

Cargo classification is not administrative paperwork. It is fundamental risk management for your import business. The distinction between general, sensitive, dangerous, and prohibited cargo determines whether your shipment moves smoothly or faces rejection or delays.

Your cargo classification decision should happen before you commit to purchasing from Chinese suppliers. It should not happen after goods are manufactured and sitting ready to ship. Early consultation with logistics specialists helps you understand the true cost, timeline, and requirements for your specific product category. This knowledge informs your sourcing decisions and protects your profit margins.

The difference between successful importing and expensive failures often comes down to one basic decision. Classify correctly from the start. Everything else follows from that foundation.