30% SoC Air Freight Compliance 2026: Battery Shipping Guide

January 1, 2026 marked a regulatory turning point when State of Charge (SoC) limits shifted from recommended to mandatory. Importers now face cargo rejection at origin airports because IATA DGR 67th Edition made 30% SoC mandatory for UN 3481 PI 966 (packed with equipment) and UN 3556 (vehicles).

Airlines conduct physical verification during dangerous goods inspection, and cargo failing the 30% threshold is immediately rejected and returned.

In our experience handling battery shipments, one electronics trader lost substantial money on an e-bike shipment because batteries shipped at 80% instead of the required 30%. The shipment contained 25 premium e-bikes valued at $45,000 total FOB. The factory had not updated their procedures to match the new mandatory requirements.

What the rejection actually cost:

Return trucking from airport to factory: $280

Airport storage fees during rejection period: $450 (3 days at $150/day)

Factory re-discharge service: $625 (25 units at $25 per discharge cycle)

Re-inspection and documentation fees: $200

Re-booking air freight at premium rates: $3,200 (40% higher than original booking)

Total additional cost: $4,755 (10.5% of shipment value)

The financial impact extended beyond direct costs. The two-week delay caused the importer to miss a product launch window, resulting in lost pre-orders worth approximately $12,000. This case demonstrates why proper SoC compliance before initial shipment is far more economical than attempting corrections after rejection.

This guide addresses the mandatory requirements that took effect January 1, 2026, the products most affected, and the practical compliance steps needed for successful air freight of battery-powered products from China.

What Changed: IATA DGR 67th Edition Mandatory Requirements

IATA DGR 67th Edition converted SoC recommendations into hard requirements effective January 1, 2026. The end of the transition period resulted in ground handling teams now rejecting non-compliant cargo during dangerous goods inspection.

Mandatory 30% SoC: Two Critical Classifications

UN 3481 PI 966 (Packed with Equipment)

Cell exceeds 2.7 Wh OR Battery exceeds 2.7 Wh triggers mandatory 30% SoC requirement

Applies when battery sits loose in packaging alongside device

Common products: Power drills with spare batteries, multi-battery drone kits, cameras with spare battery packs

Does NOT apply to batteries installed inside devices

Small batteries under 2.7 Wh (button cells, some hearing aid batteries) exempt from SoC requirements

UN 3556 (Vehicle, Lithium Ion Battery Powered)

Battery exceeds 100 Wh triggers mandatory 30% SoC requirement (or less than or equal to 25% indicated on device)

New classification specifically for electric vehicles

Applies regardless of whether battery is removable, integrated, or fixed to frame

Common products: E-bikes (250-750 Wh), electric scooters (150-600 Wh), electric skateboards

UN 3481 PI 967 (Contained in Equipment) - Still Recommended Only

Batteries installed inside devices remain under recommendation, not mandate

Examples: Smartphones, laptops, tablets with non-removable batteries

Airlines may enforce stricter policies, but not legally required

The Classification Test That Determines Compliance

Simple question: Can someone remove the battery without tools?

If the answer is yes, the product is classified as packed with equipment (PI 966) and requires mandatory 30% SoC when Cell exceeds 2.7 Wh OR Battery exceeds 2.7 Wh.

If the answer is no and removal requires pry tools or screwdrivers, the product is classified as contained in equipment (PI 967) where 30% SoC remains recommended only, not mandatory.

Last month we processed 23 e-scooter shipments from Shenzhen. Eighteen factories treated their products as general equipment, missing the UN 3556 classification entirely. All faced thermal runaway risk assessment failures during ground handling inspection.

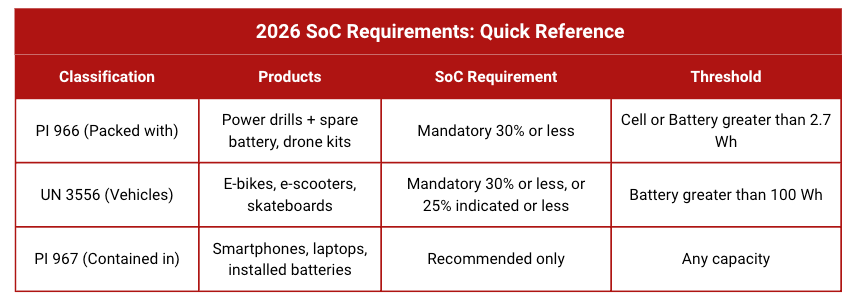

2026 SoC Requirements: Quick Reference

Note on emerging vehicle battery classifications: The 2026 regulations also introduced UN 3557 (Vehicle, lithium metal battery powered) and UN 3558 (Vehicle, sodium ion battery powered). Both follow the same 100 Wh threshold and 30% SoC requirements as UN 3556. Sodium-ion battery vehicles are beginning to appear in export markets, particularly from Chinese manufacturers developing alternative battery chemistries. If your vehicle uses sodium-ion rather than lithium-ion batteries, classification as UN 3558 requires identical State of Charge compliance.

Product-Specific Compliance Notes

Power Tools & Small Motorized Products:

Spare battery in retail package triggers PI 966 even if main battery is installed

Most power tool batteries: 20-100 Wh (well above 2.7 Wh threshold)

Common error: Factory discharges main battery, forgets the spare. This happens because production staff focus on the installed battery and overlook spare batteries sitting in accessory compartments or separate packaging within the master carton.

Pro Tip: Request factories install all batteries into devices before packaging when possible

Electric Bicycles & Scooters:

All require UN 3556 classification regardless of battery integration method. This applies whether the battery is removable, semi-integrated (requires tools for removal), or permanently welded into the vehicle structure.

Typical battery capacity: E-bikes 250-750 Wh, scooters 150-600 Wh

Discharge time: 4-8 hours per unit for large capacity batteries

Air freight cost reality: $200-375 per 25kg e-bike vs. $80-120 sea freight

Pro Tip: Sea freight with 25-35 day transit often more economical for bulk e-bike shipments

Cameras, Drones & Consumer Electronics:

Special Provision A181: Mixed packaging (installed batteries plus spares in one carton) requires the entire carton to follow PI 966 classification

Example: 10 cameras with installed batteries plus 20 spare batteries in master carton require all 20 spares to comply with 30% SoC

Battery Management System (BMS) displays showing 2/4 bars indicates 25% capacity (acceptable compliance method)

Common Classification Trap:

Robot vacuums with slide-out batteries are classified as "packed with" (requires 30%)

Not "contained in" even though battery installs into device during normal operation

This confuses many importers because the battery functions identically to a laptop battery, yet receives different classification treatment based solely on the removal mechanism

Test: No tools needed for removal triggers packed with classification

Factory Preparation: SoC Discharge Checklist

Discharge Process Requirements

Time needed per battery:

Small batteries (<20 Wh): 1-2 hours

Medium batteries (20-100 Wh): 2-4 hours

Large batteries (>100 Wh): 4-8 hours + cooling time

Discharge methods (from most to least accurate):

Load bank discharge - Industrial equipment for e-bikes/scooters, most accurate

BMS discharge stations - Professional battery manufacturers, 30min-2hr processing

Controlled device operation - Running battery through actual device until 30%

Critical requirement: Batteries must cool 2-4 hours before packaging to prevent thermal events and packaging damage. Hot batteries (45-60°C during discharge) can warp cartons and may trigger ground handling rejection if temperature sensors detect elevated heat. Airlines consider warm batteries as potential thermal runaway indicators.

Mandatory SoC Compliance Declaration Elements

Factory must provide written certification including:

Batch number or serial number range

Measurement method (voltage/coulomb counting/indicated capacity)

Actual SoC percentage or device-indicated level

Measurement date (within 7 days of air freight departure)

Authorized signature + company stamp

Reference to IATA DGR 67th Edition

Sample declaration: "We certify that lithium-ion batteries in shipment [ref] under UN 3481 PI 966 have been discharged to SoC not exceeding 30% of rated capacity, measured [date] using [method]. Batch: [numbers]. Prepared per IATA DGR 67th Edition."

Factory Verification Red Flags

Warning signs of inadequate compliance:

Claims "all batteries ship at 30% from production" (batteries are produced at higher charge for QC testing)

References "sea freight battery rules" (IMDG Code does not equal IATA DGR)

No visible discharge equipment during factory audits

Certification dated more than 7 days before shipping

No understanding of difference between "packed with" vs "contained in"

Best practice: Include SoC discharge requirements in original purchase orders and confirm factory capabilities during order acknowledgment. Allow minimum 5-7 days lead time for discharge, cooling, measurement, and documentation before planned air freight pickup dates.

Working with Dangerous Goods Specialists

Many importers discover factory compliance gaps only after cargo rejection at origin airports. At Gerudo Logistics, we conduct pre-shipment factory audits specifically for battery SoC compliance before booking air freight. Our ground operations team in Guangzhou, Shanghai, Shenzhen, and other major export hubs verifies discharge equipment capabilities, reviews documentation accuracy, and confirms proper UN classification before cargo enters the dangerous goods handling chain.

This verification approach has prevented rejection of 94% of battery shipments we handle compared to industry average rejection rates of 15-20% for first-time battery air freight. For importers shipping electric vehicles, power tools, or electronics with separated batteries, working with a freight forwarder experienced in IATA DGR 67th Edition requirements reduces compliance risk and avoids the costly re-handling cycle described in our earlier case study.

Air Freight vs. Sea Freight: Decision Framework

When to Choose Air Freight

Air freight makes economic sense when:

Product margin exceeds 50% and can absorb freight costs of $8-15 per kg

Customer penalties for late delivery exceed freight premium (typically $300-1000+ per day)

Product launch timing is absolutely critical to market entry

Inventory stockout would cause lost sales exceeding air freight cost by 3x or more

Cargo requires 5-7 day transit time to meet business commitments

Air freight challenges for battery products:

Requires verified 30% SoC documentation before acceptance

Ground handling inspection typically adds 1-2 days to total transit time

Premium rates during peak shipping periods (quarterly ends, holiday seasons)

Limited airline capacity for dangerous goods classifications due to aircraft cargo hold restrictions and regulatory limits on total lithium content per flight

When to Choose Sea Freight

Sea freight becomes the better option when:

Current inventory levels cover extended lead times (25-35 days ocean transit)

Product margin below 30% makes air freight economically unviable

Large or heavy products with low value-to-weight ratio (e-bikes, power tools, industrial equipment)

Customers accept standard lead times without penalties

No State of Charge compliance complications exist. Note that IMDG Code (ocean freight regulations) differs from IATA requirements and generally imposes fewer restrictions on battery State of Charge levels.

Strategic Approach: Hybrid Shipping

Many importers implement split shipment strategies that balance cost control against delivery timing:

70-80% of total volume via sea freight for cost efficiency

20-30% of critical SKUs via air freight for speed

Fast-moving products or high-margin items prioritized for air freight

Bulk orders or standard replenishment via ocean freight

This approach limits total air freight expenditure while protecting against inventory gaps from production delays or shipping disruptions.

Four Critical Compliance Failures That Cause Cargo Rejection

1. Misclassifying "Contained In" vs. "Packed With"

The Error: Assuming products qualify as "contained in equipment" (PI 967, exempt) when packaging actually triggers "packed with equipment" (PI 966, mandatory 30%).

The Test: Can the battery be removed without tools? If yes, the product is packed with equipment and requires 30% SoC.

Real example: Robot vacuum with slide-out battery (no tools required) qualifies as packed with, not contained in. Even though battery installs into device during use, removal method determines classification.

We reclassified a client's cordless vacuum last month. Factory insisted "contained in" because battery locked into handle. But removal required only pushing a button. Reclassified to PI 966, discharged to 30%, avoided rejection at origin.

2. Last-Minute Discharge Requests (Within 48 Hours of Pickup)

The Error: Requesting SoC discharge 24-48 hours before air freight pickup.

Why it fails: Discharge process takes 2-4 hours. Batteries reach 45-60°C during discharge. Cooling requires 2-4 hours before packaging. Documentation preparation needs time. Total cycle: 2-3 days minimum. Compressing this timeline results in incomplete discharge, inadequate cooling, or documentation errors triggering rejection.

Best practice: Communicate discharge requirements to factories minimum 5-7 days before planned air freight pickup. Factory time pressure during peak production periods creates shortcuts that lead to inadequate discharge and fire suppression failures during ground handling inspection.

3. Using IMDG Code Documentation for Air Freight

The Error: Providing sea freight MSDS and DG declarations for air freight bookings.

Why airlines reject it: IMDG Code (ocean transport) differs from IATA DGR (air transport). Some IMDG classifications allow >30% SoC under specific conditions. Airlines verify IATA DGR compliance specifically.

Correct documentation must reference: IATA DGR 67th Edition, correct Packing Instruction (PI 966/967/952), proper Section (I or II based on Wh rating).

4. Trusting "We've Always Shipped This Way"

The Error: Assuming 2024/2025 successful shipments guarantee 2026 compliance.

What changed January 1: The regulation shifted from recommendation to mandatory requirement. Some airlines enforced SoC verification pre-2026, others didn't. Now standardized enforcement applies across all IATA airlines.

Shanghai Pudong, Guangzhou Baiyun, Shenzhen Bao'an all implemented coordinated ground handling verification procedures January 1. Cargo that shipped successfully in 2025 may face rejection in 2026 with identical packaging and documentation.

Frequently Asked Questions

Q1: What is the new 30% SoC rule for 2026?

Starting January 1, 2026, IATA DGR 67th Edition made 30% SoC mandatory (not recommended) for UN 3481 PI 966 where Cell greater than 2.7 Wh OR Battery greater than 2.7 Wh are packed with equipment, and UN 3556/3557/3558 vehicles with batteries greater than 100 Wh. Airlines now reject non-compliant cargo during ground handling inspection.

Q2: Does this apply to laptops and smartphones?

No. Devices with installed batteries qualify as UN 3481 PI 967 "contained in equipment" and remain under recommendation only, not mandatory. The mandatory rule applies to spare batteries shipped alongside devices or vehicles with large battery systems. However, if you ship laptops with separate spare batteries in the same carton, those spare batteries must comply with the 30% requirement under PI 966.

Q3: How do I prove my cargo is at 30% SoC?

Factory must provide SoC Compliance Declaration including: batch numbers, measurement method, actual charge percentage, measurement date (within 7 days), and authorized signature. Many airlines also request BMS screenshots or discharge test reports for verification.

Q4: What happens if my shipment gets rejected at Shanghai airport?

You pay return trucking ($150-300), airport storage fees ($150-450 for rejection period), factory re-discharge service ($20-30 per unit), re-handling fees ($200-500), potential misdeclaration penalties, and must re-book air freight at current market rates. The total additional cost typically equals 8-12% of shipment value. More critically, you miss your delivery window entirely, which can result in customer penalties or lost sales opportunities.

Q5: Can I use 25% indicated battery capacity instead of 30% rated capacity?

Yes. IATA accepts either 30% of rated capacity OR 25% indicated on device display. The 25% indicator method works well for products with battery level displays (camera batteries, power tools with LED indicators). The difference exists because battery indicators typically show usable charge, while rated capacity includes reserve capacity that devices cannot fully access. Using 25% indicated provides equivalent safety margin to 30% rated capacity.

Q6: Who is responsible for SoC compliance—my factory or my freight forwarder?

The shipper (factory/supplier) is legally responsible for battery discharge and SoC levels. Freight forwarders verify documentation and prepare dangerous goods declarations, but cannot physically discharge batteries after receiving cargo. Discharge must happen at the factory before pickup.

Q7: Do sodium-ion battery vehicles require 30% SoC compliance?

Yes. Vehicles powered by sodium-ion batteries are classified as UN 3558 and face identical requirements to lithium-ion vehicles (UN 3556). If battery exceeds 100 Wh, mandatory 30% SoC applies. Chinese manufacturers increasingly export sodium-ion battery products as alternatives to lithium-ion chemistry, and these require the same ground handling verification procedures.

Professional Dangerous Goods Air Freight Support

Battery air freight compliance in 2026 requires coordination across multiple technical domains: accurate UN classification, factory discharge verification, proper documentation preparation, and dangerous goods declaration filing. Many importers underestimate the complexity until facing their first cargo rejection.

Gerudo Logistics specializes in dangerous goods air freight from China with dedicated focus on battery compliance under IATA DGR 67th Edition. Our services include pre-shipment factory SoC audits, UN classification verification for complex products, dangerous goods documentation preparation, and direct coordination with airline ground handling teams at major Chinese airports. We maintain operational offices in Guangzhou, Shanghai, Shenzhen, Ningbo, Qingdao, and Dalian, providing local expertise for factory coordination and compliance verification before cargo enters the air freight chain.

For importers shipping electric vehicles, power tools with spare batteries, or electronics requiring PI 966 classification, working with a freight forwarder experienced in battery air freight compliance significantly reduces rejection risk. Our team handles the technical compliance requirements while you focus on your core import business.

Conclusion

The January 1, 2026 IATA DGR 67th Edition shift from recommended to mandatory 30% SoC requirements fundamentally changed air freight compliance for battery products. Accurate classification (packed with vs. contained in), verified factory discharge, and complete documentation now determine whether cargo ships or faces rejection at origin airports.

Successful compliance requires three core elements: understanding which UN classification applies to your specific products, establishing reliable factory discharge procedures that achieve and document 30% State of Charge levels, and preparing complete dangerous goods declarations that reference IATA DGR 67th Edition requirements.

Ground handling teams at major Chinese airports including Shanghai Pudong, Guangzhou Baiyun, and Shenzhen Bao'an conduct thorough verification of SoC compliance, making proper preparation essential for avoiding costly cargo rejection and shipment delays.